Restoring a 1966–1977 Early Bronco is a commitment that blends passion, craftsmanship, and careful planning. These iconic 4x4s represent a golden era of American off-road design—simple, rugged, and timeless. Yet the path from project to finished vehicle demands realistic expectations about the cost to restore an Early Bronco, as surprises like hidden rust or worn components can quickly escalate expenses beyond initial estimates.

Important note on pricing: Costs will vary as cost of goods and labor will fluctuate from builder to builder and market pricing fluctuates as well. The ranges presented below reflect current market conditions, but your specific project may vary based on countless factors. For an accurate assessment tailored to your goals and timeline, contact ASC 4×4 directly via phone at (310) 369-6341 or through our website’s contact form.

The stakes are high: a well-executed restoration preserves history while delivering a vehicle that performs reliably today. Whether aiming for factory-correct originality or a restomod with modern drivability, understanding cost drivers helps avoid common pitfalls that derail projects and drain budgets. The difference between a successful build and a perpetual money pit often comes down to planning—knowing what to expect before writing checks.

Understanding the Scope of Your Early Bronco Restoration

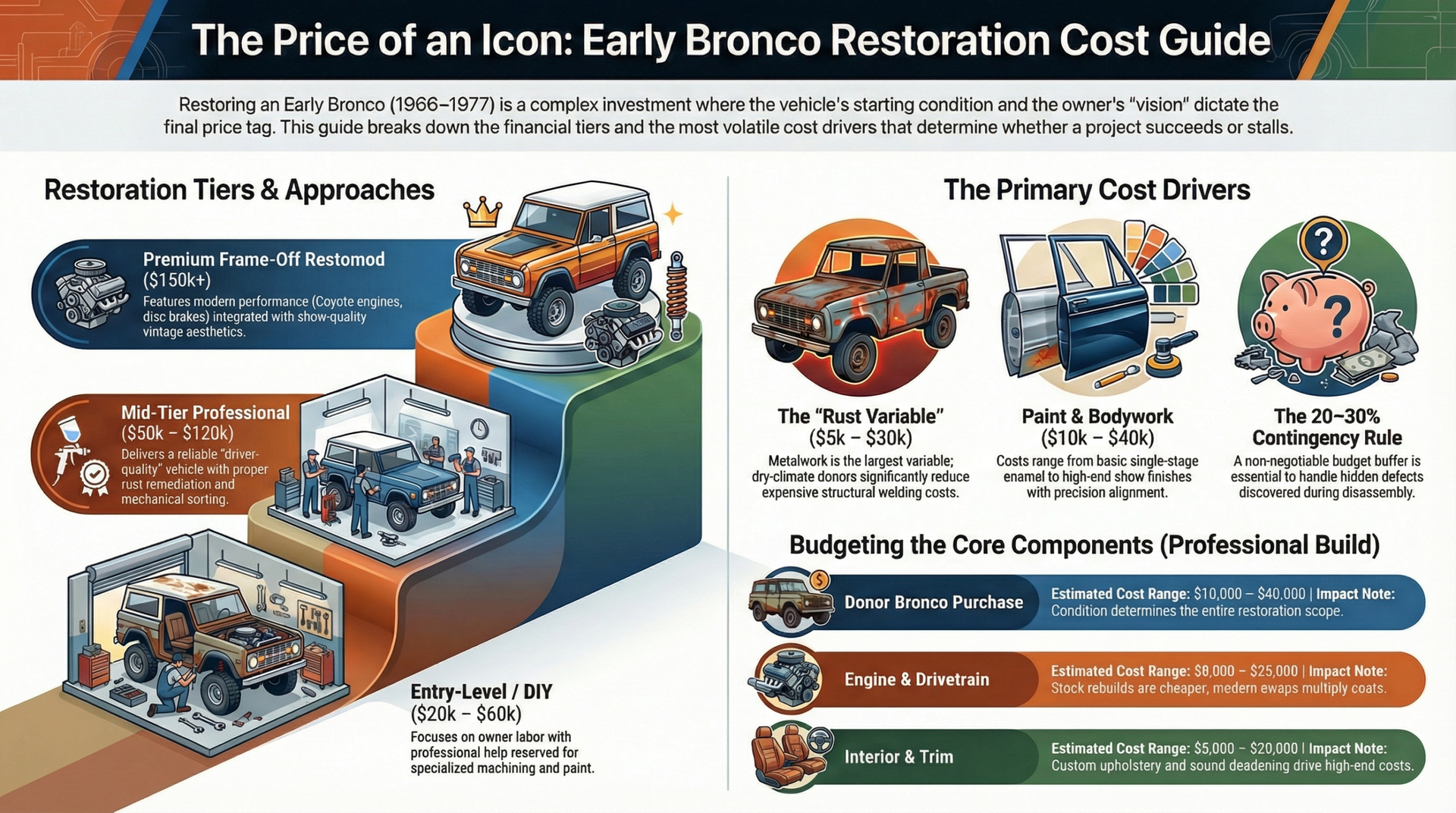

Restorations fall into distinct categories, each carrying different price implications. A pure stock restoration returns the Bronco to original factory specifications using period-correct parts and finishes. These builds appeal to collectors and purists who value authenticity over modern convenience. Restomods integrate upgrades like fuel-injected engines, power steering, disc brakes, or improved suspension while retaining vintage aesthetics—combining classic appearance with contemporary drivability. The restomod approach dominates the current market as owners seek vehicles they can actually use rather than trailer queens.

Scope dictates cost more than almost any other variable. A frame-off restoration involves complete disassembly, with body separated from frame, every component inspected or replaced, and systematic reassembly. This approach is thorough but labor-intensive—expect hundreds of hours in professional shop time. Lighter refreshes target cosmetics and mechanical essentials while leaving sound components in place. The frame-off early bronco restoration cost runs substantially higher than partial rebuilds, but delivers superior results when the donor vehicle warrants such investment.

Your Bronco’s starting condition is pivotal to final project cost. A solid, low-rust example saves thousands in metalwork. Vehicles from dry climates—Arizona, Nevada, Southern California—command premium prices precisely because they minimize the single largest variable expense. Severe corrosion in structural areas demands extensive repairs or panel replacement, and early bronco rust repair costs escalate rapidly once metalwork begins. The price difference between a solid southwestern truck and a rust-belt example often exceeds the acquisition premium within months of teardown.

Key Drivers of Cost in Early Bronco Restoration Projects

Costs vary widely based on factors that interact in complex ways. Understanding these drivers enables realistic budgeting before commitment.

Initial Vehicle Price and Condition: Donor vehicles range from $10,000 basket cases to $40,000+ solid runners. The early bronco project cost equation starts here, but purchase price inversely correlates with restoration expense—cheap trucks cost more to restore. A $35,000 solid example may reach completion for less total investment than a $12,000 rust bucket.

Extent of Rust: Common problem areas include floors, rockers, tailgate, inner fenders, door posts, and frame rails. Surface rust responds to treatment; perforation requires cutting and welding. Early bronco body restoration cost spikes when multiple panels need replacement. A floor-and-rocker job runs $5,000–$15,000 depending on severity; add door posts and inner structure, and metalwork alone approaches $30,000 at professional rates.

Mechanical Needs: Engine rebuilds, transmission overhauls, axle reconditioning, and steering box rebuilds add predictable costs. The early bronco engine rebuild cost for a stock 289 or 302 runs $4,000–$8,000 for quality machine work and assembly. Transmission rebuilds add $1,500–$3,500. Swaps to modern drivetrains—fuel-injected Coyote engines, overdrive transmissions—multiply these figures but deliver superior reliability and performance.

Paint Quality and Body Alignment: Single-stage enamel differs from base/clear by thousands of dollars. Color changes require jamb and interior work that same-color resprays avoid. Panel gaps and body alignment demand skilled labor—poor fit compounds paint cost through repeated adjustments. Professional early bronco paint cost ranges from $10,000 for quality single-stage to $40,000+ for show-level finishes with extensive bodywork.

Interior Refresh: Stock replacement interiors using quality reproduction components run $3,000–$8,000 in parts alone. Custom upholstery, upgraded seating, and sound deadening push early bronco interior restoration cost toward $15,000–$20,000 for comprehensive builds.

Contingencies for Discoveries: Disassembly reveals problems invisible during inspection. Budgets without contingency fail. Period.

Realistic Ranges for Early Bronco Restoration Costs

Budgets span broad ranges reflecting the variables above. These figures represent 2025–2026 market realities based on actual completed projects.

Entry-Level/DIY Approach ($20,000–$60,000): Heavy owner labor on a fundamentally sound vehicle. Owner performs disassembly, prep work, basic mechanical service, and reassembly. Professional involvement limited to specialized tasks: machine work, welding, paint. Requires substantial time investment—hundreds of hours—plus tools and workspace. Mistakes add expense; the DIY early bronco restoration cost advantage erodes when rework enters the equation.

Mid-Tier Professional ($50,000–$120,000): Solid driver-quality results from competent shops. Addresses all mechanical and structural needs without extensive customization. The professional early bronco restoration cost in this range delivers reliable vehicles with good cosmetics and proper rust remediation. Most practical builds land here.

Premium Frame-Off Restomod ($150,000+): Modern performance integrated with vintage styling. Fuel-injected engines, upgraded suspension, disc brakes, climate control, and show-quality finishes. Custom fabrication and engineering elevate these builds beyond bolt-on modifications. The high-end early bronco restomod cost reflects hundreds of hours in skilled labor plus premium components throughout.

These ranges stem from donor condition, regional labor rates, and parts quality decisions. Geographic variation matters: Southern California shop rates exceed rural Texas rates by 30–50%. For a detailed estimate based on your specific project goals, contact ASC 4×4 at (310) 369-6341 or submit an inquiry through our website’s contact form.

Sample Budget Worksheet for Early Bronco Restoration Costs

This practical breakdown provides planning benchmarks. Adjust for specific conditions and regional pricing.

| Category | Range | Notes |

|---|---|---|

| Donor Bronco Purchase | $10,000–$40,000 | Condition determines restoration scope |

| Rust/Metal Repair & Panel Replacement | $5,000–$30,000 | Largest variable; inspection critical |

| Engine/Transmission Rebuild or Swap | $8,000–$25,000 | Stock rebuild vs. modern swap |

| Suspension, Brakes, Steering | $5,000–$15,000 | Stock refresh vs. upgraded components |

| Paint, Bodywork, Alignment | $10,000–$40,000 | Quality level drives cost |

| Interior, Upholstery, Trim | $5,000–$20,000 | Reproduction vs. custom |

| Electrical, Wiring, Accessories | $3,000–$10,000 | Harness replacement often necessary |

| Contingency (20–30%) | $10,000–$30,000+ | Non-negotiable budget line |

Total estimate ranges: $56,000–$210,000+ depending on scope and starting point. The how much to restore an early bronco question has no single answer—only ranges bounded by specific project parameters. These figures exclude labor if owner-performed. Professional labor at $75–$150/hour transforms part costs into total project costs. A $3,000 suspension kit becomes $6,000 installed. Multiply across every system for realistic professional build budgets.

For an accurate quote tailored to your specific vehicle and goals, reach out to ASC 4×4. We provide comprehensive project assessments based on detailed inspection and your desired outcome. Call (310) 369-6341 or use our contact form to schedule a consultation.

DIY vs. Professional vs. Hybrid Approach – Decision Guide

The restoration approach question requires honest self-assessment regarding skills, tools, time, and tolerance for learning curves.

DIY Restoration

Advantages: Significant labor cost savings—potentially $30,000–$60,000 on a comprehensive build. Personal satisfaction and intimate knowledge of the vehicle. Flexibility to work at your own pace.

Disadvantages: Time-intensive; expect 500–1,500 hours for frame-off work. Requires substantial tool investment and dedicated workspace. Skill gaps produce costly errors. Quality ceiling limited by experience level. Projects often stall or extend indefinitely.

The DIY vs professional bronco restoration decision hinges on realistic capability assessment. Mechanical work suits motivated amateurs with basic competence. Welding, bodywork, and paint demand skills that take years to develop—amateur execution shows.

Professional Restoration

Advantages: Expertise ensures precision across all disciplines. Faster timeline with dedicated shop resources. Accountability and warranty coverage on work performed. Access to specialized equipment and supplier relationships.

Disadvantages: Higher upfront cost. Less control over daily progress. Quality varies significantly between shops—vetting essential.

Hybrid Approach

Advantages: Optimal value extraction. Owner handles disassembly, cleaning, parts procurement, and reassembly of simple components. Professionals manage complex work: welding, machining, paint, critical mechanical assembly.

Disadvantages: Requires coordination between owner and shop. Project scheduling complicated by multiple parties. Communication failures create friction.

Most successful projects blend approaches strategically. The best early bronco restoration approach matches task complexity to available skills while respecting time constraints.

Common Mistakes Buyers Make

Avoidable errors account for substantial budget overruns across early bronco projects. Recognition enables prevention.

Underestimating Rust Severity: Surface appearance deceives. Perforated metal hides beneath undercoating, carpet, and sound deadening. Early bronco restoration budget planning must account for discoveries—assume worse than visible. The worst rust hides in boxed sections and seams where inspection access is limited.

Skipping Thorough Pre-Purchase Inspection: Professional inspection costs $200–$500 and prevents $20,000 mistakes. Magnet testing, seam probing, and systematic evaluation reveal hidden conditions. The inspection cost represents the highest-ROI expenditure in any project.

Failing to Budget Contingency: Twenty to thirty percent contingency is not conservative—it’s realistic. Projects without contingency funds stall when discoveries exhaust allocated budgets. This mistake kills more restorations than any technical failure.

Choosing Low-Quality Reproduction Parts: Budget parts fit poorly, fail prematurely, and require replacement. The early bronco parts cost difference between quality reproductions and cheap imports often doubles in installation labor when fitment issues arise. Buy once, cry once.

Rushing Without Clear Vision: Projects initiated without defined scope and budget meander. Scope creep accumulates expense without corresponding value. Define the build before starting; deviate deliberately rather than accidentally.

Overlooking Long-Term Value of Professional Craftsmanship: Amateur bodywork and paint depreciate vehicle value. Professional execution in visible areas—paint, interior, panel gaps—determines perceived quality regardless of mechanical excellence. Saving money on cosmetic work costs money at sale.

ASC Standards

Quality at ASC 4×4 means meticulous attention to structural integrity as the foundation for everything else. Rust remediation follows proper protocols: complete removal of compromised metal, quality replacement panels, thorough corrosion protection including cavity wax and seam sealing. Panel gaps receive the attention that separates professional work from amateur efforts.

Builds emphasize long-term reliability over cutting corners—using proven methods and premium materials without shortcuts that create future problems. Whether stock restoration or thoughtful restomod, the standard remains consistent: vehicles built to perform reliably while respecting the Bronco’s heritage. Practical craftsmanship means daily-driver durability, not show-only fragility.

Why Early Broncos Are Worth the Investment

These vehicles offer unmatched character among vintage 4x4s. The 1966–1977 design achieved proportions and simplicity that later vehicles abandoned. Compact dimensions, excellent visibility, and genuine off-road capability distinguish Early Broncos from bloated modern SUVs.

The investment value of early bronco restoration extends beyond financial return to usability—properly executed builds serve as reliable transportation rather than garage ornaments. Market values have appreciated consistently over the past decade. Quality restorations command premium prices; poorly executed projects languish. The early bronco value appreciation trend rewards proper execution while penalizing shortcuts.

Vehicles done right—structurally sound, mechanically sorted, cosmetically correct—hold value and often appreciate. Compromised builds depreciate regardless of money spent. Done right, Early Broncos deliver usable classic vehicle ownership: weekend canyon runs, beach trips, trail access, and daily errands in a vehicle that draws attention and sparks conversation. The restoration investment purchases experiences unavailable in modern vehicles.

Frequently Asked Questions

How much should I budget for a full Early Bronco restoration?

Expect $50,000–$150,000+ depending on scope, starting condition, and finish level. Begin with detailed inspection to establish realistic baseline before committing funds. Remember that costs vary significantly based on builder rates, parts availability, and market conditions. For a personalized budget assessment based on your specific project, contact ASC 4×4 at (310) 369-6341 or through our website’s contact form.

Is DIY restoration cheaper?

Yes for labor cost, but requires skills, tools, time, and workspace. Many DIY projects add expense through mistakes requiring professional correction. Honest skill assessment prevents costly surprises.

What drives the biggest costs?

Rust repair and bodywork frequently exceed initial estimates, followed by mechanical rebuilds and paint. These three categories account for 60–70% of typical project budgets.

Should I buy a project or already restored Bronco?

Projects save upfront purchase cost but risk higher total expenditure when restoration costs exceed estimates. Restored examples offer immediate enjoyment with known total investment. The calculation depends on your skills, time availability, and risk tolerance.

Can I make my Early Bronco a daily driver?

Yes, especially with restomod upgrades addressing reliability and comfort: fuel injection, overdrive transmission, power steering, disc brakes, and improved cooling. Stock configurations function as daily drivers but require more attentive maintenance.

How long will restoration take?

Six to twenty-four months or longer depending on approach, shop workload, and parts availability. DIY projects often extend to three to five years. Professional frame-off builds typically run twelve to eighteen months with dedicated shop scheduling.

What if my Bronco has heavy rust?

Prioritize structural repairs—floors, rockers, door posts, frame—before cosmetics. Costs rise significantly but quality metalwork preserves long-term value. Reproduction tubs offer alternatives to extensive repair when damage exceeds practical remediation thresholds.

Do you handle remote coordination for out-of-area clients?

Yes—ASC serves serious builds in Southern California and coordinates remotely with clients nationwide for consultation, parts sourcing, and project oversight.

Ready to discuss your Early Bronco project?

Contact ASC 4×4 for consultation and evaluation. Expertise in restoration planning, realistic budgeting, and quality execution for serious builds.

ASC 4×4 | (310) 396-6341

Sources:

- https://kincerchassis.com/restoring-broncos-early-bronco-restoration-guide

- https://www.reddit.com/r/bronco/comments/1cw797r/how_much_would_it_cost_to_restore_1974_bronco?referrer=grok.com

- https://www.fullsizebronco.com/threads/how-much-would-a-full-restoration-cost-for-a-second-gen-bronco.526667?referrer=grok.com