Rust is the single greatest threat to any 1966–1977 Ford Bronco. These vehicles spent decades exposed to moisture, road salt, and off-road elements, making rust nearly inevitable in key structural areas. While surface rust is manageable, perforation in floors, rockers, door posts, wheel wells, frames, and tailgates demands serious intervention. This article explains everything you need to know about Early Bronco rust repair.

Serious buyers often discover rust during inspections, turning dream projects into costly realities. Proper remediation isn’t about quick fixes—it’s about precision removal, quality replacements, and proactive protection for decades of reliability.

Why Rust is the #1 Challenge in Early Bronco Restorations

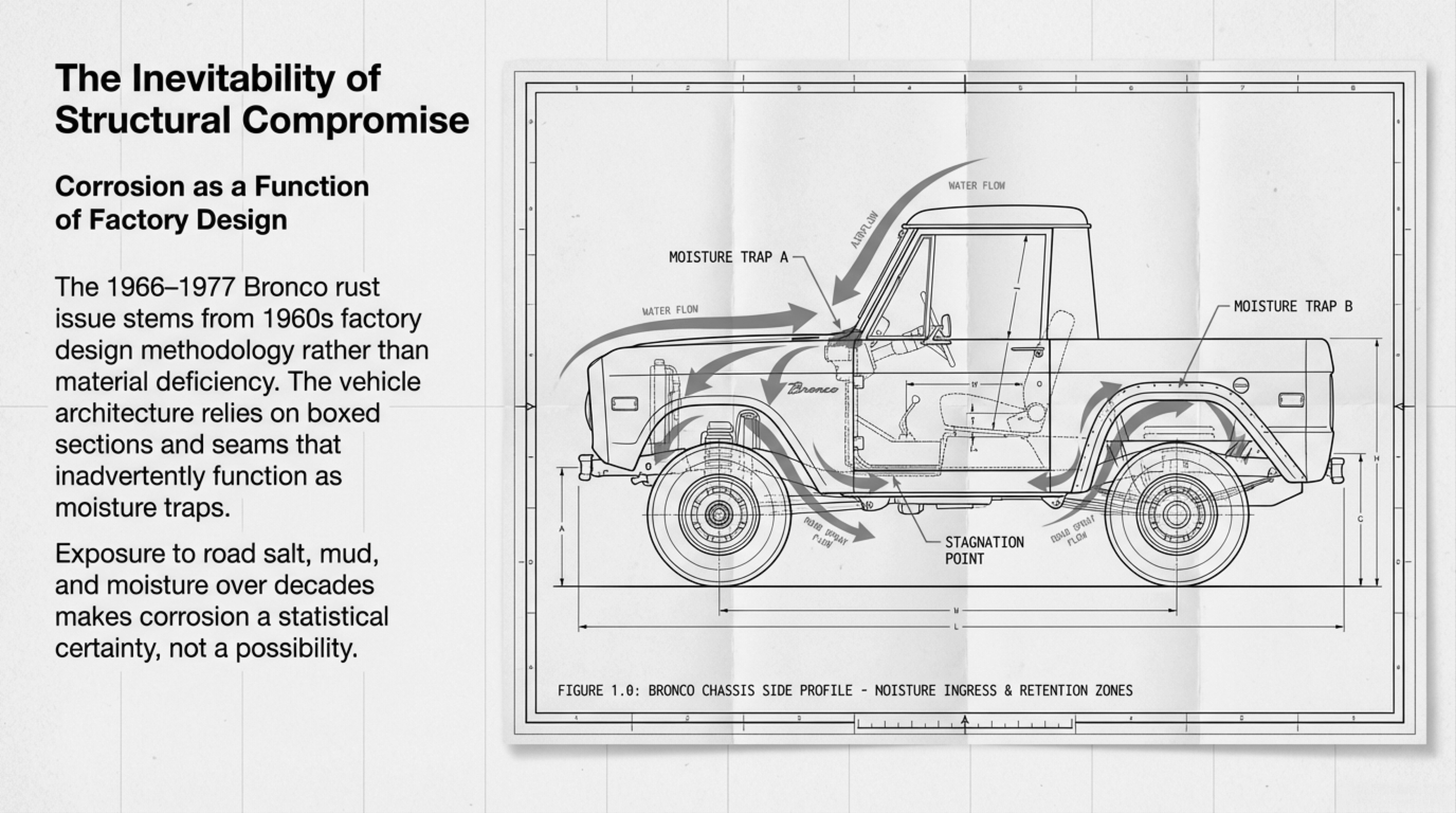

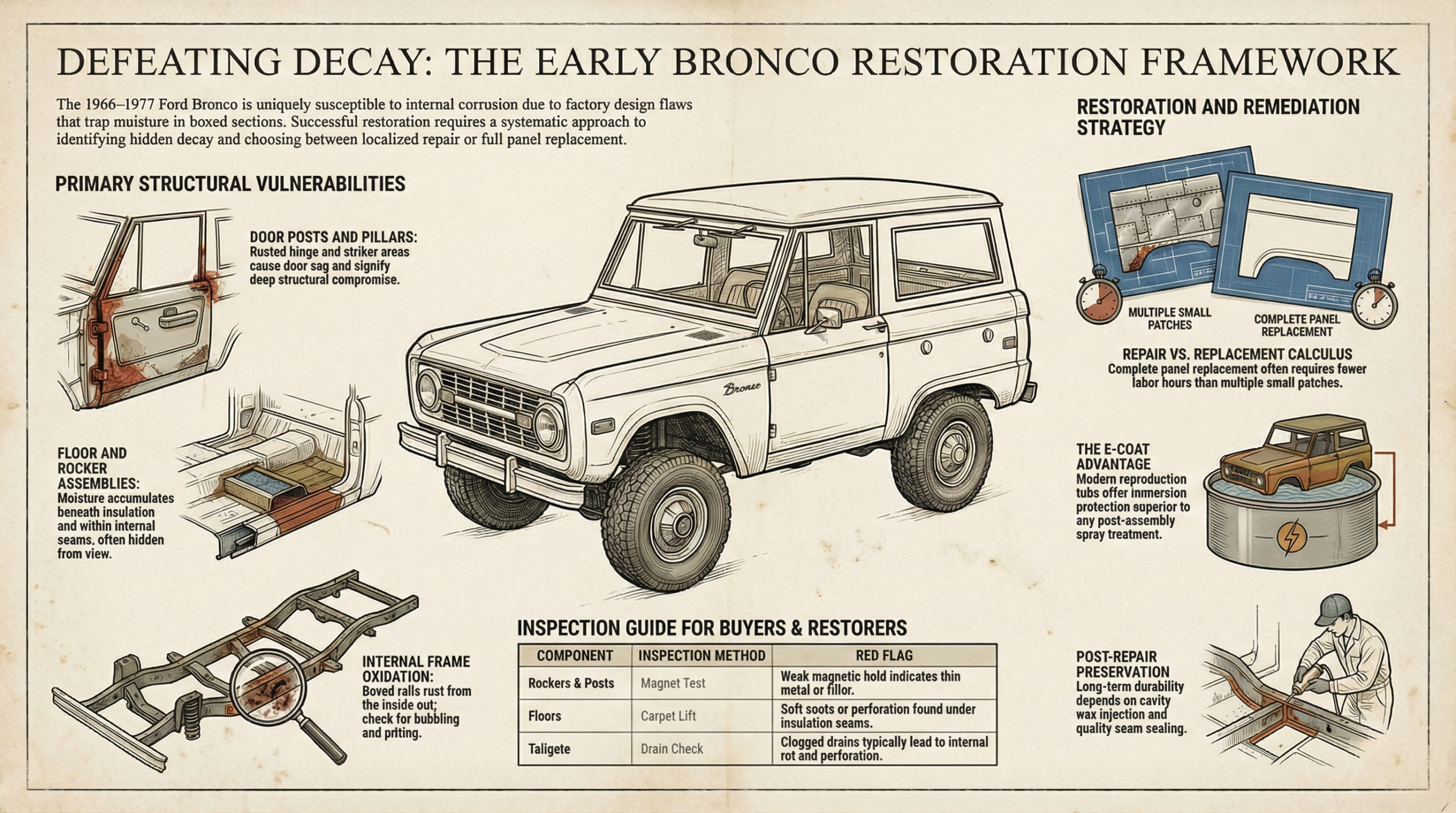

Early Broncos were built tough, but their design traps moisture in boxed sections and seams. Floors and rockers collect debris, door posts hold water from poor drainage, and frames rust from inside out. Untreated rust compromises safety, alignment, and value. Understanding early bronco corrosion issues is fundamental to any restoration project—the 1966-1977 bronco rust problem stems from factory design rather than material deficiency.

Common Early Bronco Rust Areas: Floors, Rockers, Door Posts, and More

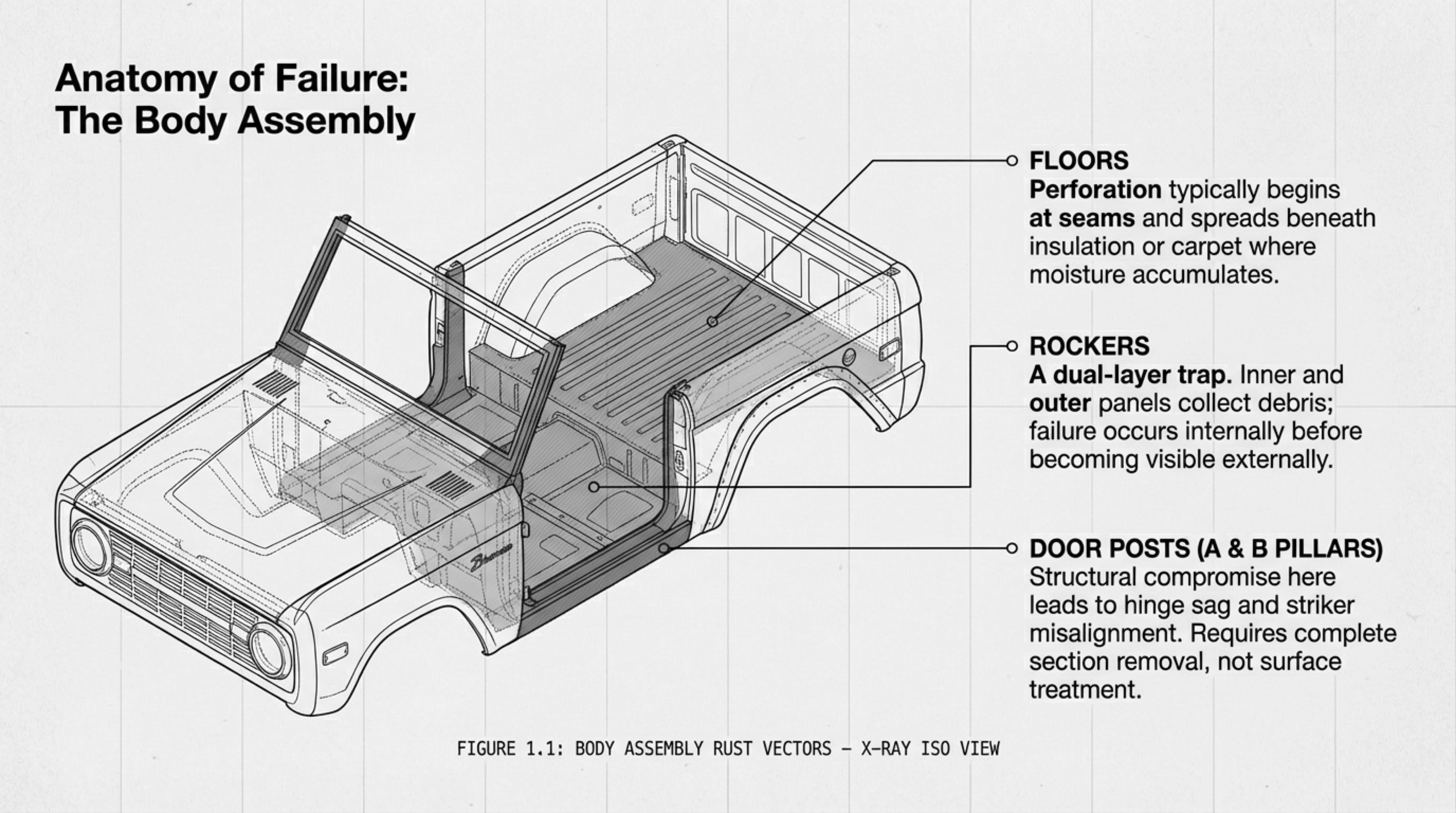

Floors: Often perforated under carpet or undercoating; check with a magnet for thin spots. Classic bronco floor rust typically begins at seams and spreads beneath insulation where moisture accumulates. Bronco floor pan rust replacement is among the most common interventions required.

Rockers: Outer and inner panels trap dirt; seams fail first. Early bronco rocker panel rust develops internally before becoming visible, making early bronco rocker panel replacement a frequent necessity.

Door Posts (A- and B-pillars): Hinge and striker areas sag when rusted, affecting door fit. Bronco door post rust compromises structural integrity and door operation simultaneously—dealing with rust in bronco door posts requires complete section removal rather than surface treatment.

Wheel Wells and Tailgate: Exposed to spray; tailgates often rot from plugged drains. Early bronco wheel well rust and bronco tailgate rust repair rank among the most visible restoration challenges. Rust in bronco quarter panels often accompanies wheel well deterioration.

Frame: Boxed rails rust internally; inspect for pitting. Early bronco frame rust and bronco frame corrosion represent the most serious structural concerns—early bronco frame rust treatment cannot be deferred once detected. Early bronco undercarriage rust spreads rapidly once protective coatings fail.

These areas require early detection—many appear solid until stripped. Hidden rust spots early bronco owners discover during teardown frequently exceed initial estimates.

Inspection Checklist: How to Spot Hidden Rust Before It Spreads

Inspecting for rust in classic ford bronco purchases requires systematic evaluation. Early bronco rust detection depends on thorough methodology rather than casual observation. Buying early bronco check for rust protocols should include:

- Lift carpet/floor mats—probe floors for soft spots.

- Use a magnet on rockers and posts—weak hold indicates thin metal.

- Open doors fully—check for sag or misalignment signaling post rust.

- Inspect wheel wells and tailgate drains—clear clogs.

- Examine frame rails—look for bubbling or holes.

- Check seams—probe with a pick for hidden perforation.

- Document with photos—compare to known good examples.

Common rust areas on 1966-1977 ford bronco bodies follow predictable patterns. Ford bronco rust prone areas cluster where water collects and drainage fails. Common bronco rust spots warrant attention regardless of apparent condition.

Repair vs. Replacement: Evaluating Your Options

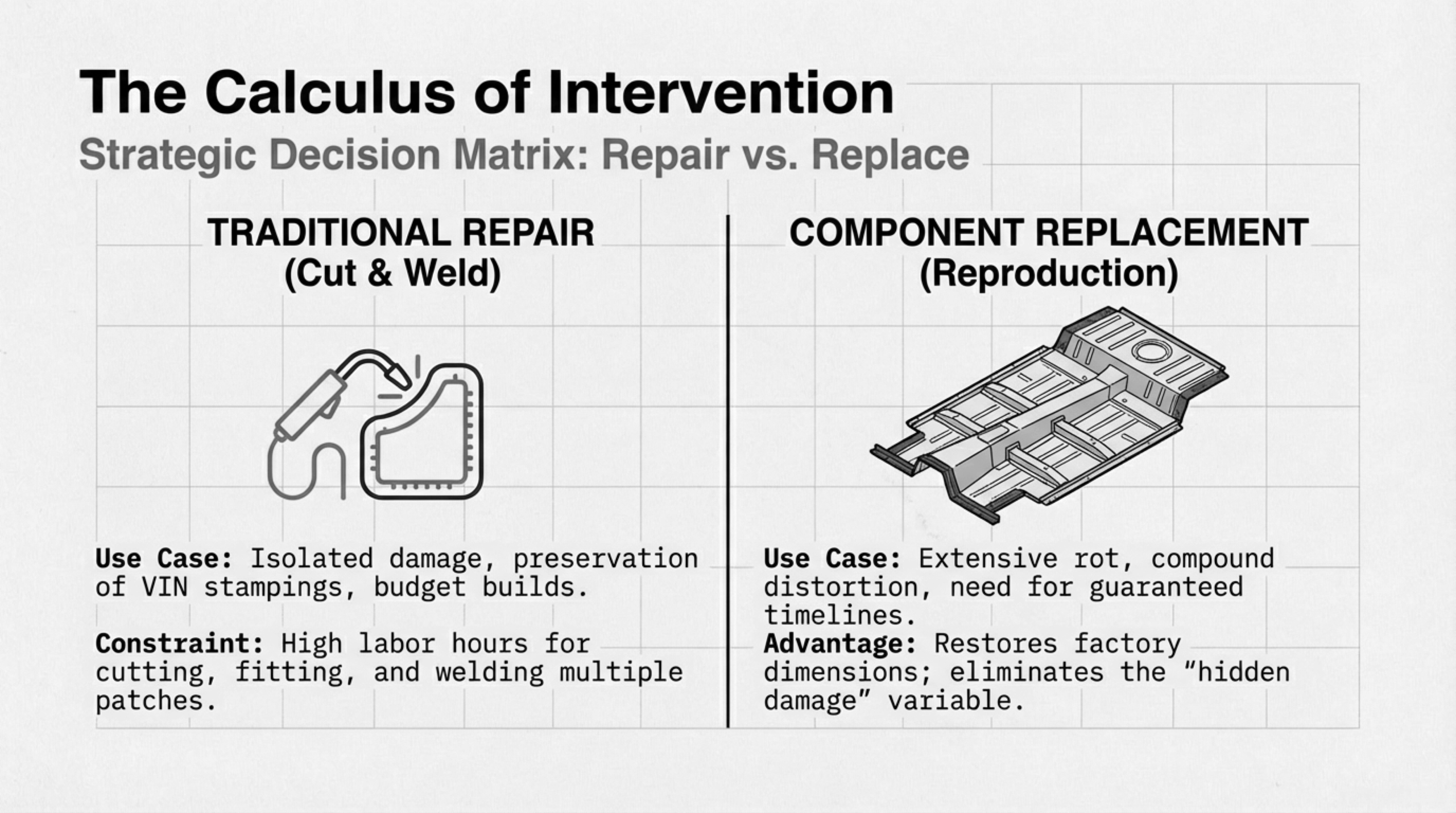

Early bronco restoration rust challenges present a fundamental decision point: repair existing metal or replace with new panels. Rust repair on 1966-1977 bronco body structures once meant fabricating patches or sourcing scarce NOS components. The reproduction panel market has transformed this calculus.

When Traditional Repair Makes Sense

Fixing perforated rust early bronco sections through cut-and-weld methods remains appropriate when:

- Rust damage is isolated to small, accessible areas

- Original stampings carry documentation or provenance value

- Panel fitment in specific areas proves problematic with available reproductions

- Budget constraints favor incremental repair over wholesale replacement

- The vehicle retains matching VIN stampings on repairable panels

Rust remediation early bronco specialists can address localized damage efficiently. Bronco rust holes repair through welded patches maintains originality when executed properly. Vintage bronco rust treatment combined with quality fabrication preserves factory character.

The Reproduction Panel Option

The early bronco aftermarket now supplies comprehensive replacement solutions from individual patch panels through complete reproduction tubs. This availability fundamentally changes the restoration economics for vehicles with extensive early bronco tub rust.

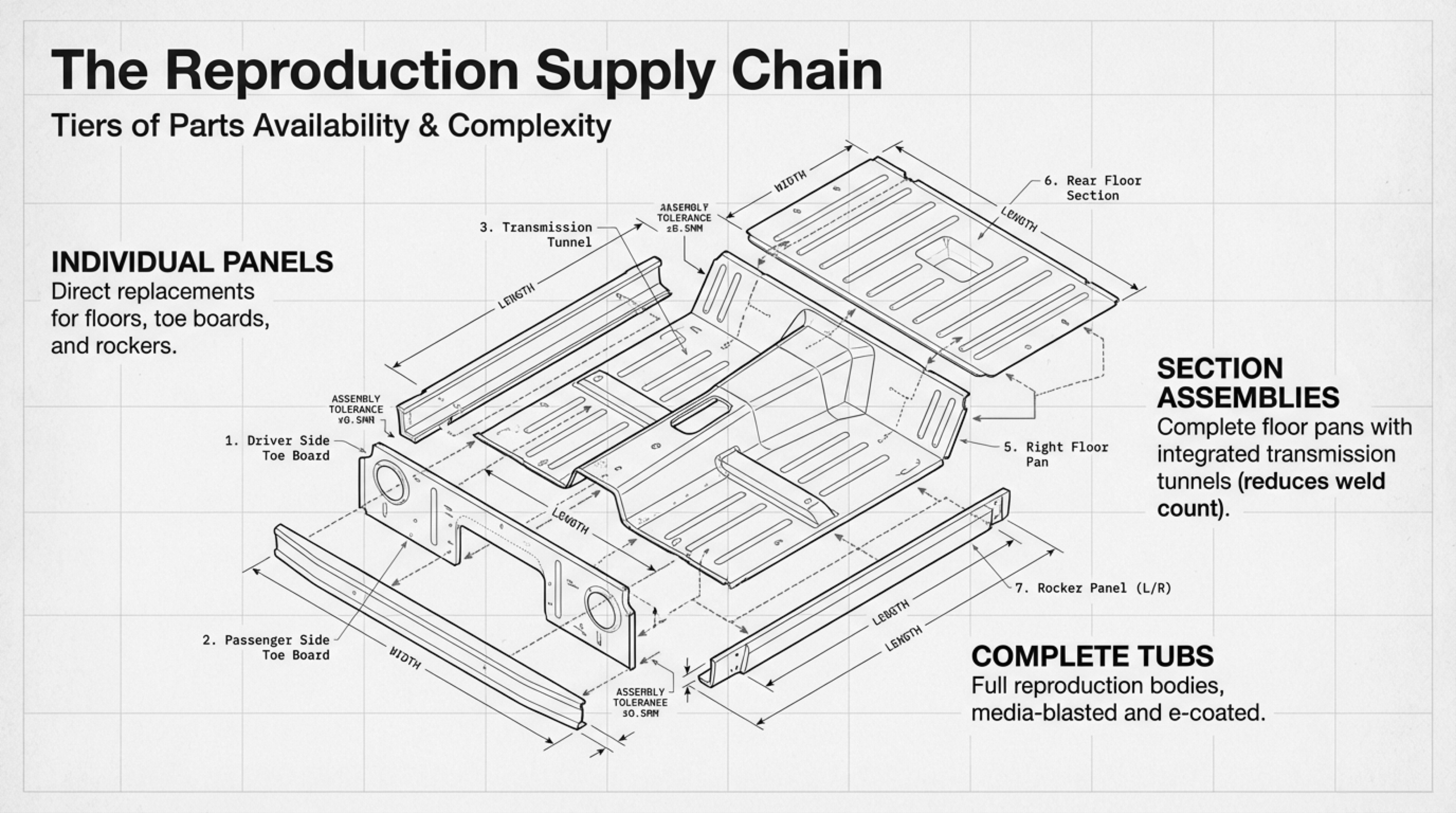

Individual Replacement Panels: Manufacturers produce direct-replacement components for virtually every rust-prone area: floor pans, toe boards, rocker panels, door posts, wheel wells, quarter panels, and tailgates. How to fix rust in early bronco floors now involves choosing between patch sections and full floor pan assemblies. Early bronco panel rust repair increasingly means bolt-in or weld-in replacement rather than fabrication.

Section Assemblies: Partial assemblies combining multiple panels—such as complete floor assemblies with integrated toe boards and transmission tunnels—reduce weld count and improve dimensional accuracy versus piecing individual components.

Complete Reproduction Tubs: Multiple manufacturers now produce complete reproduction bodies for 1966–1977 Broncos. These new-production tubs arrive media-blasted and e-coated, with enhanced spot weld patterns exceeding factory specifications. Restoring rusted early bronco vehicles with severe classic bronco body rust now permits complete tub replacement rather than extensive metalwork.

Cost-Benefit Analysis Framework

The repair-versus-replace decision requires honest assessment across multiple factors:

Labor Hours: Cutting, fitting, and welding multiple patch panels accumulates labor rapidly. A complete floor replacement may require fewer hours than repairing eight separate perforations. Early bronco restoration guide rust repair estimates routinely undercount actual labor when damage exceeds initial assessment.

Hidden Damage: Perforation visible during inspection typically indicates more extensive corrosion beneath. Repair-as-you-go approaches discover additional rust mid-project, compounding costs. Reproduction panels eliminate this variable.

Dimensional Integrity: Extensively rusted tubs often exhibit compound distortion. Reproduction bodies maintain factory dimensions without the accumulated stress of decades and previous repairs. Door gaps, fender alignment, and weatherseal fitment benefit accordingly.

Coating Quality: Production reproduction tubs receive immersion e-coat superior to any post-assembly treatment. Hidden cavities, boxed sections, and weld seams receive complete coverage unachievable through spray application to assembled bodies.

Time to Completion: Projects stall when rust repair reveals unexpected damage. Replacement panels or complete tubs establish predictable timelines.

Evaluating Reproduction Quality

Not all replacement panels meet equivalent standards. Assessment criteria include:

Material Gauge: Quality reproductions match original steel thickness. Lightweight panels compromise structural integrity and weld compatibility.

Stamping Accuracy: Contours, mounting holes, and dimensional tolerances determine fitment. Poor reproductions require extensive modification.

Coating: Bare steel panels demand immediate treatment. E-coated panels resist handling damage and provide superior primer adhesion.

Weld Flanges: Replacement panels must integrate with adjacent original or reproduction components. Flange dimensions and locations affect assembly sequence and structural continuity.

Manufacturer Reputation: Established suppliers like Dynacorn maintain quality control systems. Lesser-known sources vary significantly.

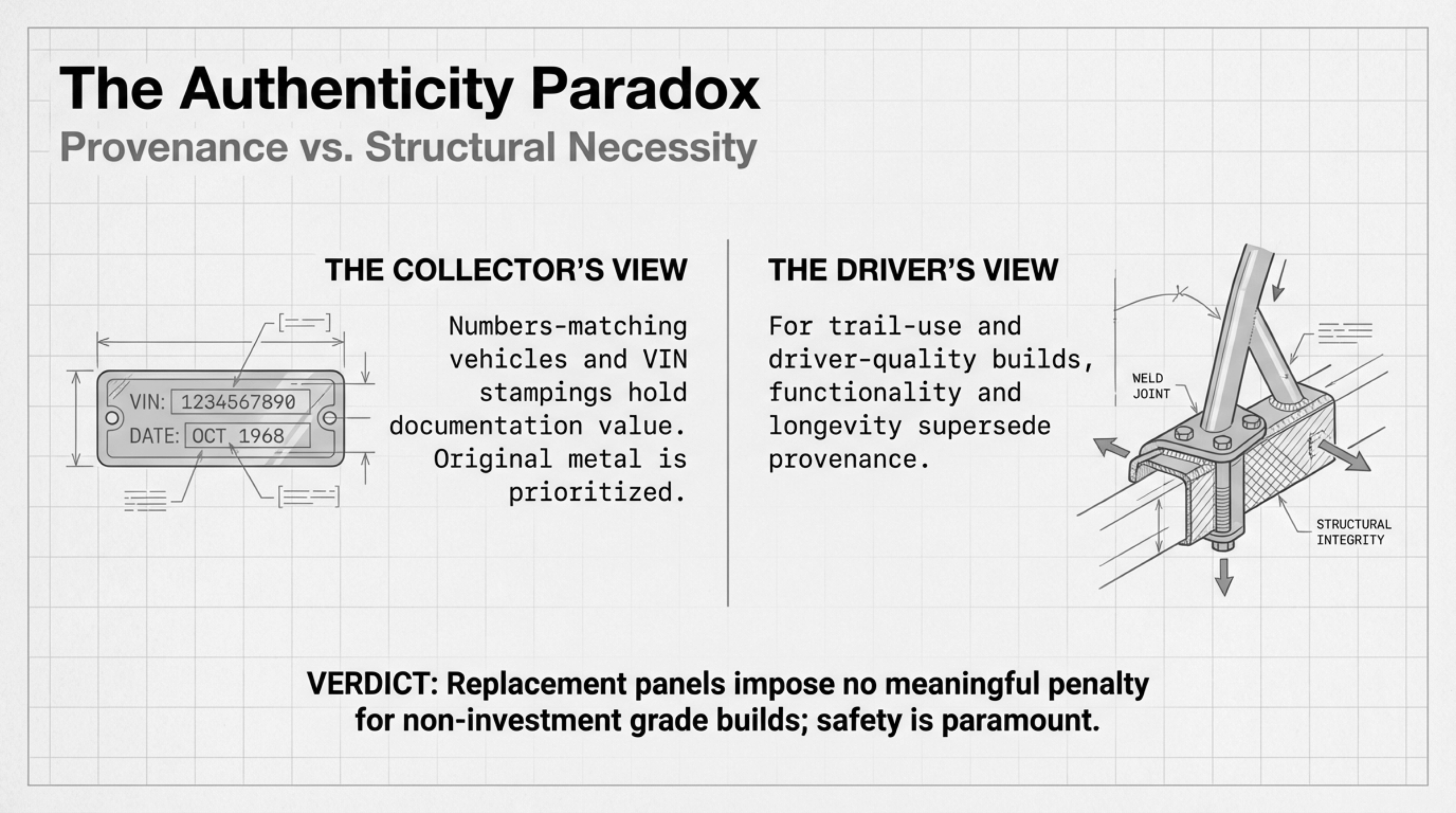

Originality Considerations

Numbers-matching vehicles present specific concerns. VIN stampings, date codes, and factory assembly marks hold documentation value for certain restorations. Replacement panels sacrifice these markers. Buyers in concours or investment categories should weigh authenticity requirements against structural necessity.

For driver-quality restorations and trail-use builds, reproduction panels impose no meaningful penalty. Functionality and longevity supersede provenance.

Hybrid Approaches

Many restorations combine strategies: reproduction floors and rockers with repaired door posts, or a complete replacement tub mounted to a reconditioned original frame. The optimal approach matches intervention intensity to damage severity by area.

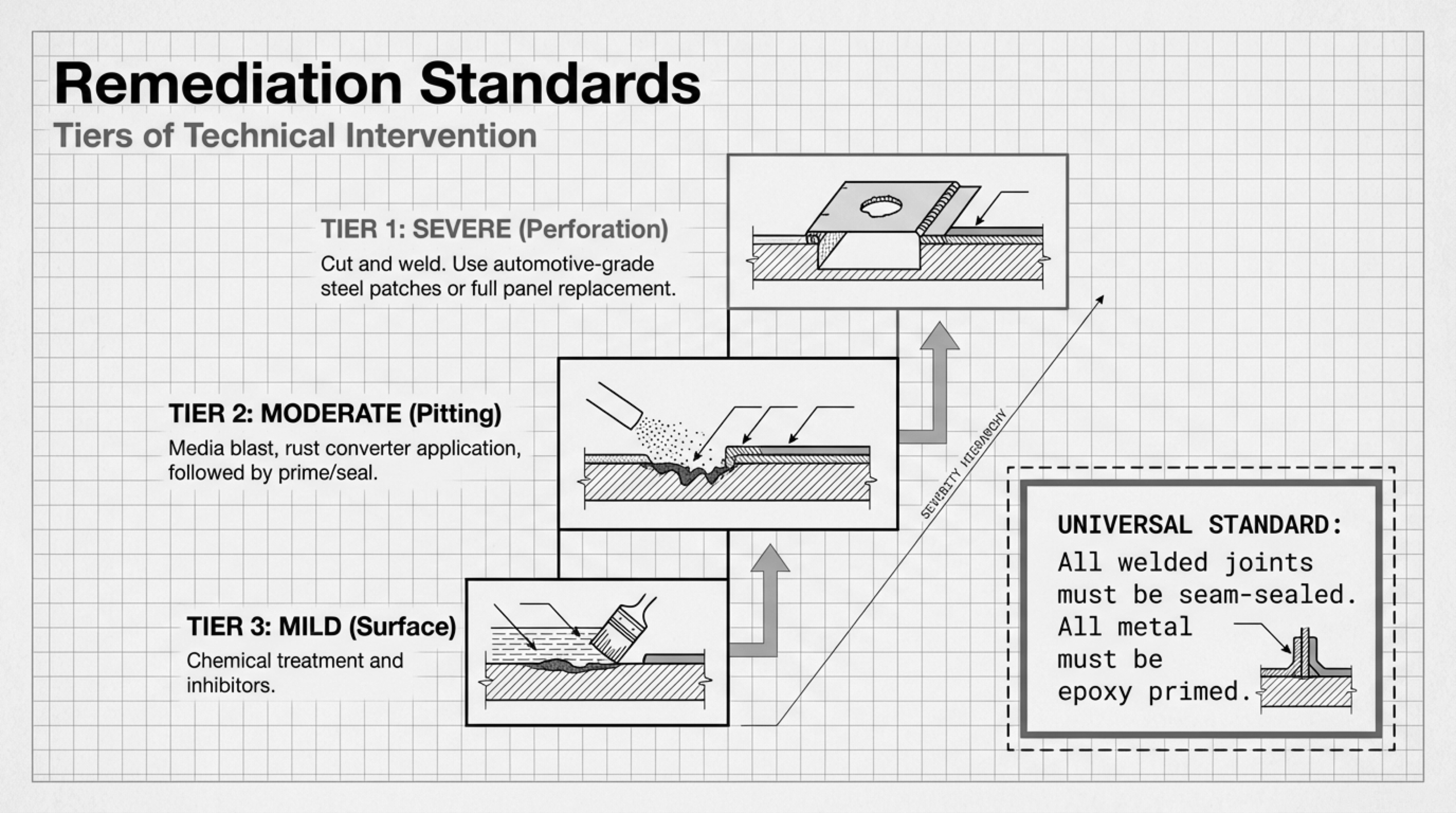

Remediation Standards: Cut, Replace, or Treat?

Severe perforation: Cut out affected sections; weld in new metal using patch panels or full floors/rockers. Use automotive-grade steel matching original gauge. Complete panel replacement often proves more efficient than multiple patches when early bronco rust areas cluster. Bronco restoration rust severity dictates intervention level.

Moderate rust: Media blast, treat with rust converter, then prime/seal.

Mild surface: Chemical treatment plus inhibitors.

Always seam-seal welds and apply epoxy primer. For tubs beyond saving, consider reproduction bodies with enhanced spot welds and e-coat. Classic bronco restoration increasingly favors replacement over extensive repair when damage warrants.

Best Practices for Long-Term Corrosion Protection

Bronco rust prevention after repair determines whether intervention proves durable:

- E-coat/immersion primer for hidden areas

- Cavity wax injection in rails/posts

- Quality seam sealer on all welded joints

- Undercoating applied correctly (avoid trapping moisture against panels)

- Regular inspections and washing, particularly after salt exposure

These practices apply equally to repaired original panels and new reproductions. Early bronco restoration rust recurrence stems from inadequate protection rather than repair method.

Questions to Ask a Shop Before Early Bronco Rust Repair

- Do you cut out all rusted metal or patch over it?

- What steel gauge and type do you use for fabricated patches?

- Do you media blast and e-coat after metalwork?

- How do you handle seam sealing on welded joints?

- Will repairs affect door alignment and body lines?

- What’s your process for rust in door posts and structural members?

- Have you evaluated reproduction panels versus repair for my vehicle?

- What warranty applies to rust remediation work?

- Can you provide references for similar early bronco rust repair projects?

Conclusion

Rust remediation sets the foundation for a solid Early Bronco. The reproduction panel market now offers alternatives that didn’t exist a decade ago—complete replacement may prove more economical and durable than extensive repair when rust damage reaches critical thresholds. Honest assessment of existing damage, realistic cost comparison, and clear project goals determine the appropriate path. Done right, whether through meticulous repair or strategic replacement, rust remediation restores structural integrity and long-term value.

ASC 4×4 https://www.asc4x4.com | (310) 369-6341

Sources:

- https://kincerchassis.com/restoring-broncos-early-bronco-restoration-guide

- https://tomsoffroad.com/blogs/education/early-bronco-restoration-hub

- https://www.ford-trucks.com/forums/542255-1967-bronco-rust-problems.html

Recommended Reading:

Contact Us

Have questions about our process? Use the form below to contact us. Our team is dedicated to providing prompt and comprehensive responses to all your questions. Let’s connect and make your classic vehicle dreams a reality!